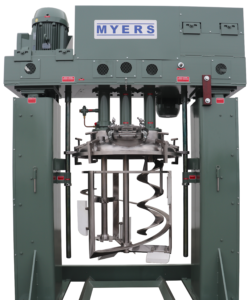

Tri-Shaft Model 550/500

Model 550/500 Tri Shaft Mixer – Used for High Viscosity Applications up to 5,000,000 cp.

The 550/500 Series Dual Shaft is designed to efficiently process a wide variety of products having high viscosity and poor flow characteristics. Due to the high viscosity of many of the products produced on the 550 design, the slow speed mixing impeller functions not only as a pump, moving the mass into the high speed dispersing blade, but also as a dispersing blade itself. With high viscosity products, the shear of the liquid layers and the friction of the particles shearing against each other cause considerable dispersion, as the slow speed impeller circulates the batch.

There are many blade configurations available to address a wide variety of product parameters.

You may also want to see our Dual Shaft and Ram Press.

Submit Application Check list for process evaluation and quotation.

- Hoist or tank mounted

- Air over oil hydraulic lifts

- Optional electric lifts

- Single and dual hoist designs

- Vacuum and non-vacuum

- Explosion-proof and TEFC motor options

The Model 550/500 is commonly used for many applications:

- Printing inks

- Wood fillers

- Epoxy mastics

- Polyester gel coats

- Silicone caulking compounds

- Polysulfide and butyl caulks

- Emulsion-type vinyl latex

- Sealants

- Rubber adhesives

- Moisture cured urethane coatings

- Textured and latex paints

- Magnetic media slurry

- Creams

- Toothpastes

Application:

Results:

Problem:

Solution: